Grease-covered Galley’s extraction systems not only create a perfect environment for bacteria but lead to increased fire hazards. Industry standards for Health and Safety require regular cleaning of the systems.

By installing approved access doors, or using existing ones, our technicians access the ductwork and after applying a non-corrosive degreaser, the grease is removed through a combination of scraping, scrubbing and drying.

Difficult to access areas are cleaned using rotary cables equipped with special nylon heads. The kitchen extractor will be removed (where possible), scrubbed and cleaned. Laundry extractor systems, clogged with dust and lint, do not allow the hot air produced by tumble dryers to be extracted efficiently. Overheated hot air can lead to ignition and cause a fire.

Once disconnected from the tumble dryers, our technicians can access the ducting which is cleaned along its entire length up to the extractor. A portable auxiliary extractor is installed at the exit of the duct, allowing the residual dirt to be removed.

On completion of the work, together with a full photographic report, a certificate for the successful removal of fire hazards is issued.

Galley Fan Before | Galley Fan After |

Grease Trap Before | Grease Trap After |

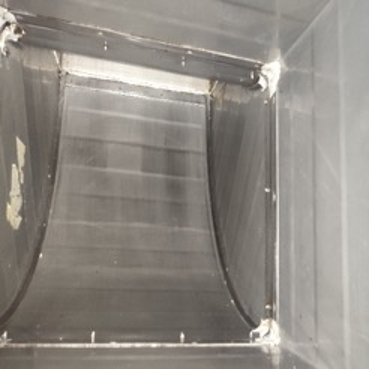

Before |

After |

Before |

After |

Before |

After |

Before |

After |

Before |

After |